SPAB – Society for Protection of Ancient Buildings: Free guidance notes: Very useful information when you own or care for a traditional or historic building. Click on the following link. https://www.spab.org.uk/advice/technical-advice-notes

Author Archives: nick

Bisley News Articles

Minchinhampton church article

Article written by the architect Antony Feltham-King looking back at the project (click on the link above)

Minchinhampton Holy Trinity Church

September/October 2017

Work has recently started on the so-called ‘re-ordering’ works at the church. Re-ordering essentially involves making changes to the layout and seating arrangements of the church which is often dictated either by changes to liturgical practice within the Church or a desire to make the space more versatile and flexible.

At Holy Trinity this will involve the removal of the fixed pews, taking up the stone pavings/flagstones, re-siting of the font, re-siting of the Rood screen, installing underfloor heating and laying a new limestone floor to the main nave and aisle areas (and relaying of some original flags in the Lady Chapel). New services will be installed including new boiler and electrics.

Prior to works commencing a pre-construction asbestos report identified the presence of asbestos so this had to cleared.

Initial site set up works (i.e. enabling works) included site protection works such as forming ply boxes around vulnerable tombs and head stones in the church yard and protection of various parts of the fabric internally.

Archaeological investigation works form a very important part of such a project and we have been lucky to work with the acclaimed archaeologist Chiz Harwood of Urban Archaeology, who is also working at Gloucester Cathedral at the moment. Chiz is keeping a blog of his work at Minchinhampton and his page is well worth a visit: http://urban-archaeology.blogspot.co.uk

To date, he has made some very special finds as can be seen.

Over the last couple of weeks we have spent time carefully taking up stone flags, reducing levels and exposing some important archaeological features.

Over the next week, or two, the aim is to carry out some structural invention works as well as start the process of importing the base layers (or fill) for the sub-floor construction.

The upper layer of this fill comprises a 150mm layer of recycled foam glass (RFG) which acts as an insulation layer for the underfloor heating system.

The following are a few images taken over the last 3 weeks.

12th Oct 2017

Unfortunately, some unforeseen structural works have had to be carried out over the last couple of weeks involving forming a reinforced concrete slab to bridge over numerous soft spots in the church floor. Engineer, Gary Wood (SFK Consulting) is the project structural engineer and felt a belt and braces approach was required to mitigate any floor settlement in the future. A labyrinth of mesh and steel reinforcing has been laid and a concrete slab cast over a large area of the church floor.

Two ‘finds’ worthy of mention include, an old drainage culvert which runs from north to south under the church floor. It was installed to take rainwater and/or ground water from the north elevation to the south. It is clearly well built and was capped with some very large capping stones which have now been removed and replaced with smaller and stronger prestressed lintels (which now facilitate the floor construction work now in hand).

The second find, is a well-constucted underground water storage tank located under the stone-flag floor of the Sacristy. Discussions are now underway to decide what is the best course of action with this particular feature.

Minchinhampton church

The project involves internal alterations to the west-end Porch Room and includes the provision of new WCs, including one with wheelchair access, and alterations to upgrade the kitchen. Some stonework repairs have been carried out to the rear-elevation parapet wall (see below). Three courses of frost-damaged masonry have been taken down and rebuilt. Two courses of replacement stone have been incorporated using Limpley Stoke base bed stone. The stonework has been bed and pointed in NHL3.5, sharp sand and Daglingworth stone dust mortar and finished with a stiff brush to give a ‘vapour-open’ surface texture (this is to maximise evaporation at the mortar face – i.e. to maximise ‘breathability’).

Internal alterations are well under way now with various walls having been removed. New steel work has been inserted (to support the roof structure) and new drains and services installed. The new division walls will soon be built; this will sub-divide the space and form the new male and female WC’s in addition to the disabled access WC.

Problems to date: The felt-flat roof is leaking in two places and a decision is to be made whether to patch the roof up or renew the covering completely. The advantage of totally renewing also means insulation can be added over the joists to make the roof into a ‘warm roof’.

More details to follow

Harescombe church

We are in the process of carrying out some careful excavations in the churchyard; this excavation work has been subject to a full archaeological watching brief by Absolute Archaeology (www.absolutearchaeology.co.uk) and to date our finds include some possible Saxon floor tiles, potential evidence of a previous building under the chancel and some fragments of human bones (which is only to be expected!)

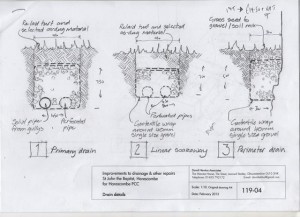

The excavation work is necessary as part of the installation of new land drains and the refurbishment of the rainwater disposal system. The church has suffered the effects of dampness due to excessive ground water and also high outside ground levels for many years and the drainage work is aimed at moving more of the ground and surface water away from the building. Other conservation works are also being carried out at the church including consolidation of sensitive and friable surfaces using the latest nano-lime technology. The work is being carried out under the watchful eye of David Newton in his capacity as the surveyor of the fabric.

The abutments have been stripped out and new lead soakers installed. A lime mortar fillet will be applied over this detail. Lime mortar repairs/repoint to open joints of the bell-cote. NHL5 was used for these repairs due to the exposed nature of these elements.

Minor pointing and some micro-pin repairs (using 3mm diameter stainless-steel bar) were needed to the cross. The dove-tail shaped, cast-iron bell supports (4 No. in total) have been carefully removed, re-painted using a high-performance paint system and reset using 12mm stainless-steel threaded bar set in epoxy-resin. The bells have been temporarily removed by Whites of Appleton in order that the mechanism can be cleaned, repaired and refitted. One of the bells is reputed to date from around 1180 making it the oldest bell in Gloucestershire!

The next phase of work includes conservation repairs to: the Norman font (the thing that babies are dunked in), the piscina (the thing that’s used for washing the communion vessels and nothing else!) and the stone reredos (the ornate feature on the east wall behind the alter which can be stone or wood and usually depicts a religious scene of some form or other).

We will be using nano-lime for the consolidation of friable surfaces along with stainless-steel micro-pins and conservation mortar repairs where necessary. We will be using highly acclaimed conservation specialist Mark Hancock (www.centrelinestone.co.uk) for this work.

More details to follow.